We have created a awesome theme

Far far away,behind the word mountains, far from the countries

DC graphene film heating

Item discription

KPF DC Heating Film

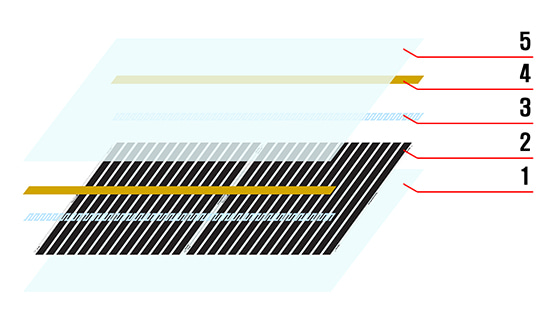

DC heating film uses silver paste due to the limitation of the resistance value of carbon paste, and cuts the carbon paste by printing it on the carbon paste coating film, realizing a DC heating film by shortening the distance of the carbon paste

div>

Existing low-resistance carbon paste resistance value

Resistance(Ω/sq, 20㎛) - 15 ± 10

Ultra-low resistance carbon paste resistance value

Resistance(Ω/sq, 20㎛) - 10 or less

Resistance(Ω/sq, 20㎛) - 15 ± 10

Ultra-low resistance carbon paste resistance value

Resistance(Ω/sq, 20㎛) - 10 or less

In addition, by increasing the print thickness (coating amount) of carbon paste and silver paste by itself, the resistance value is lowered to realize a DC heating film in the shape of an existing heating film

carbon paste 70μm -> 110μm

Increase carbon paste print thickness by about 30% or more

Silver paste 50μm -> 80μm

Increase the thickness of silver paste by 30% or more

As a result, DC heating film is implemented in the form of AC heating film to suppress unit price increase, uniformity of products produced, and convenience of operation

DC graphene film

An obstacle to the use of DC film, which is more efficient and safer than AC heating film, as it is difficult to use the DC heating film in large numbers due to the high unit price of silver paste

In addition, since the power consumption of the heating film is determined according to the printing interval of the silver paste on the upper surface after printing carbon paste, it is difficult to inspect during the work, and it is difficult to work within the required power consumption

Carbon paste is basically used by mixing high resistance and low resistance in different proportions depending on the product. need

KPF collaborated with Daehan Ink to develop an ultra-low-resistance carbon paste that lowered the resistance value of the existing low-resistance carbon paste by 30%

In addition, since the power consumption of the heating film is determined according to the printing interval of the silver paste on the upper surface after printing carbon paste, it is difficult to inspect during the work, and it is difficult to work within the required power consumption

Carbon paste is basically used by mixing high resistance and low resistance in different proportions depending on the product. need

KPF collaborated with Daehan Ink to develop an ultra-low-resistance carbon paste that lowered the resistance value of the existing low-resistance carbon paste by 30%