We have created a awesome theme

Far far away,behind the word mountains, far from the countries

PTC freeze protection heating wire

Item discription

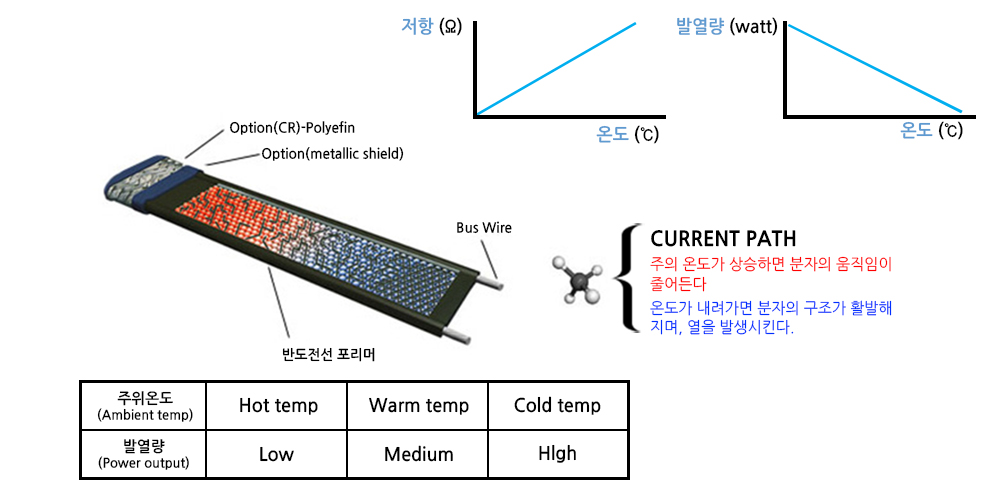

Unlike the existing heating wire, it is not a metal heating wire, but a product that generates heat by a plastic semiconductor (semi-conductor) containing carbon

It has PTC (Positive Temperature Coefficient) characteristics

It has PTC (Positive Temperature Coefficient) characteristics

PTC Characteristics: It is a kind of natural phenomenon. It refers to a phenomenon in which the amount of heat automatically increases/decreases according to changes in ambient temperature.

PTC heating wire is a self-regulating heater developed by applying the PTC principle. It has the advantage of minimizing electricity consumption because it generates less heat when the temperature is warm.

The semiconductor plastic is specially treated to maintain the initial amount of heat even after long-term use

PTC heating wire is a self-regulating heater developed by applying the PTC principle. It has the advantage of minimizing electricity consumption because it generates less heat when the temperature is warm.

The semiconductor plastic is specially treated to maintain the initial amount of heat even after long-term use

Are you going to use a product without electrical appliance safety certification?

Will you use products that are used for 1-2 years and discarded?

FireWorried about Worried about the product?

Will you use products that are used for 1-2 years and discarded?

FireWorried about Worried about the product?

From now on, electrical appliances are certified safe.

Replace it with a fireworry-free product that can be used for more than 10 years.

You will be relieved from all your worries.

Replace it with a fireworry-free product that can be used for more than 10 years.

You will be relieved from all your worries.

Product Features

- Safety

-

With the self-control system, there is no fear of overheating and there is no electromagnetic wave.

- Keep a constant temperature

-

It detects the ambient temperature and adjusts the amount of heat generated by the cable

- Electric energy saving

-

This is a system that automatically reduces the amount of heat generated when the temperature rises.

- My configuration

-

Corrosion-free and semi-permanent in a way towards heat treatment and crosslinking

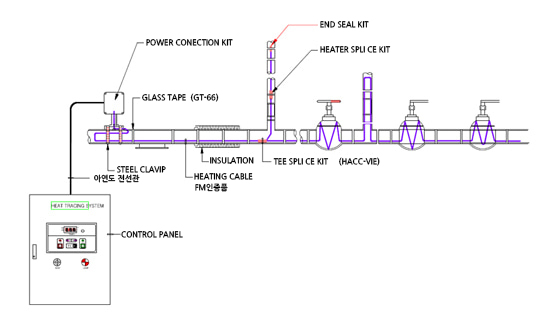

pipe dressing system

1. The heat draping system is designed to prevent freezing and maintain temperature and is composed as follows.

Freeze protection PTC carbon heating cable, power connection kit, power connection enclosure, temperature sensor/temperature controller, small selection box, terminal treatment kit, fixing tape, warning label, thermal insulation material and moisture-proof hot rolled product, Power panel

2. Checklist for freezing prevention PTC carbon heating cable

1) Before installing the heating cable, make sure that it is identical to the product in the specification, and visually check that there is no damage to the product.

2) The heating cable should be stored in a dry and clean cape, and do not connect the power while it is wound on a reel or drum

3) For rapid temperature rise, energy saving, and prevention of overheating of plastic pipes or fluids, PTC carbon heating cables must have the following S-R index values.

S-R idex is an output value expressed in W/℃, measured between 10℃ and 30℃.

4) To check whether the thermal performance comparison test specified in IEEE515:2004 has been passed, the heating cable is maintained at each temperature for 15 minutes and between 25℃ and 65℃ (for KPF series) or between 25℃ and 110℃ (In the case of KPF-R series), the output after 1500 thermal cycle tests should be more than 90% of the minimum output.

5) Heating cables are KPF-CP, KPF-CF that can be used at a continuous operating temperature of 65℃ and instantaneous exposure temperature of 85℃, or KPF-R-CX, KPF that can be used at a continuous operating temperature of 110℃ and instantaneous exposure temperature of 135℃. Must be -R-CF

2) The heating cable should be stored in a dry and clean cape, and do not connect the power while it is wound on a reel or drum

3) For rapid temperature rise, energy saving, and prevention of overheating of plastic pipes or fluids, PTC carbon heating cables must have the following S-R index values.

S-R idex is an output value expressed in W/℃, measured between 10℃ and 30℃.

4) To check whether the thermal performance comparison test specified in IEEE515:2004 has been passed, the heating cable is maintained at each temperature for 15 minutes and between 25℃ and 65℃ (for KPF series) or between 25℃ and 110℃ (In the case of KPF-R series), the output after 1500 thermal cycle tests should be more than 90% of the minimum output.

5) Heating cables are KPF-CP, KPF-CF that can be used at a continuous operating temperature of 65℃ and instantaneous exposure temperature of 85℃, or KPF-R-CX, KPF that can be used at a continuous operating temperature of 110℃ and instantaneous exposure temperature of 135℃. Must be -R-CF

3. Things to check before installing cables

1)Pipe Make sure that all equipment related to piping is installed properly and related tests have been completed.

2) Do not install PTC carbon heating cables until pipes and accessories are installed and related tests and painting are completed.

3) The surface of the piping and accessories in the place where the heating cable will be installed must be cleaned so that there is no oil, dust, or metal fragments.

2) Do not install PTC carbon heating cables until pipes and accessories are installed and related tests and painting are completed.

3) The surface of the piping and accessories in the place where the heating cable will be installed must be cleaned so that there is no oil, dust, or metal fragments.

4. Cable Installation

1) When installing, prepare an extra cable for power connection and cable connection. Refer to KPF's design guide and prepare the heating cable spares required for accessories such as valves and flanges.

2) In the case of an elbow, place the heating cable on the outside radius of the elbow to secure sufficient heat. In the case of pipe supports, insulated pipe supports do not require additional heating cables, otherwise, heating cables twice the length of the pipe supports and an additional 40 cm are required.

3) Additional heating cables are required to compensate for the increased heat loss caused by valves and other accessories. For additional required cable length for other parts, refer to KPF's design guide and select it.

4) Install the valve and other parts by bending the heating cable well for easy maintenance.

5) Finish the circuit underside using a termination kit.

6) If necessary, use a connection kit to connect power connections between heating cables.

2) In the case of an elbow, place the heating cable on the outside radius of the elbow to secure sufficient heat. In the case of pipe supports, insulated pipe supports do not require additional heating cables, otherwise, heating cables twice the length of the pipe supports and an additional 40 cm are required.

3) Additional heating cables are required to compensate for the increased heat loss caused by valves and other accessories. For additional required cable length for other parts, refer to KPF's design guide and select it.

4) Install the valve and other parts by bending the heating cable well for easy maintenance.

5) Finish the circuit underside using a termination kit.

6) If necessary, use a connection kit to connect power connections between heating cables.

5. Installation of insulation

1) In some cases, the heat loss is too high to offset the heat loss with the heating cable alone without the insulation material, so it is important to install an appropriate insulation material.

2) Install the insulation material immediately after installation of the heating cable is completed to prevent possible physical damage.

3) The insulation material must be thoroughly finished to prevent penetration of moisture, etc.

4) Insulation should be installed on exposed heat sinks such as pipe supports, hangers, flanges, valve bonnets, pumps, and valves.

2) Install the insulation material immediately after installation of the heating cable is completed to prevent possible physical damage.

3) The insulation material must be thoroughly finished to prevent penetration of moisture, etc.

4) Insulation should be installed on exposed heat sinks such as pipe supports, hangers, flanges, valve bonnets, pumps, and valves.

6. After installation is complete

1.) After the insulation is installed, the insulation resistance of the branch circuit should not be less than 10Mohm at 500Vdc.

2) After installing the insulation, attach the warning label on the outside in a position where it can be seen from the ground.

3) It is recommended to record the voltage, current, pipe temperature and ambient temperature after driving the circuit by applying the rated voltage and current.

This information can be used for future reference and is necessary for maintaining driving records.

2) After installing the insulation, attach the warning label on the outside in a position where it can be seen from the ground.

3) It is recommended to record the voltage, current, pipe temperature and ambient temperature after driving the circuit by applying the rated voltage and current.

This information can be used for future reference and is necessary for maintaining driving records.

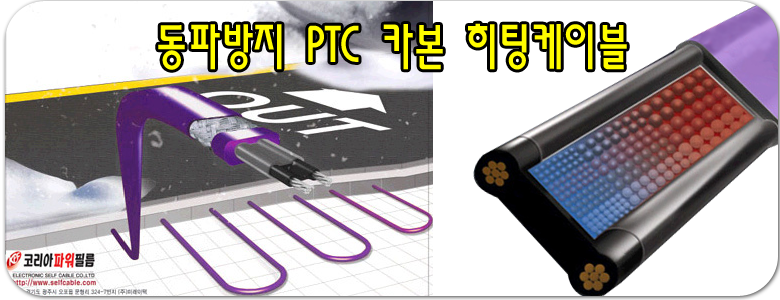

Snowmelting system

1. Checklist for freezing prevention PTC carbon heating cable

Before installing the heating cable, check that the part number, horn voltage, output, and type printed on the heating cable cover are correct.

Visually inspect the product for damage.

Visually inspect the product for damage.

2. Composition and Features

1) Snow melting system using self-controlled heating cable

Suitable for concrete pavement. A polymer crosslinked through electron beam irradiation along two nickel-plated copper wires

As a parallel structure surrounded by PTC material, it is covered with an insulating jacket with excellent physical properties, and has an electrical grounding protection function through tin-plated copper braiding

The output changes according to the temperature, so there is no risk of overheating, and it can be cut to the desired length on site.

There is no need to connect the PTC carboning cable and the cold lead to enter the distribution box.

100~120Vac without the use of a transformer. It can be used by selecting a power source of 200~240Vac.

Power connection and terminal processing of the PTC carbon heating cable must be done in a panel or terminal box.

Power consumption is between 200 and 300W/㎡, and is determined by considering road pavement materials and underlying conditions.

Suitable for concrete pavement. A polymer crosslinked through electron beam irradiation along two nickel-plated copper wires

As a parallel structure surrounded by PTC material, it is covered with an insulating jacket with excellent physical properties, and has an electrical grounding protection function through tin-plated copper braiding

The output changes according to the temperature, so there is no risk of overheating, and it can be cut to the desired length on site.

There is no need to connect the PTC carboning cable and the cold lead to enter the distribution box.

100~120Vac without the use of a transformer. It can be used by selecting a power source of 200~240Vac.

Power connection and terminal processing of the PTC carbon heating cable must be done in a panel or terminal box.

Power consumption is between 200 and 300W/㎡, and is determined by considering road pavement materials and underlying conditions.

2) Construction

The PTC carbon heating cable must be fixed and supported on reinforcing bars or wire mesh (wire mesh) before installation.

Terminal boxes and panels must be installed on the ground and must be waterproof.

Each circuit must be protected by an earth fault protection device operating at 300mA.

Field work is possible for power connection, terminal insulation, and connection between heating cables.

For safety, metal pipes exposed to the public must be protected with a metal barrier or insulating material.

The end of the PTC carbon heating cable must be closed using a terminal key.

After installation is complete, measure the resistance between the buswire and the braid with a 500Vdc insulation resistance tester before pouring concrete.

(Measured value must not be less than 200MΩ)

PTC carbon heating cable must not be disturbed during concrete pouring work.

A flexible conduit must be installed in the section where the PTC carbon heating cable exits from the road to a panel or terminal box.

Only one heating cable must be inserted in the conduit.

In order to cure the concrete, the heating cable must not be powered on for at least 7 days after the concrete is installed.

The PTC carbon heating cable must be fixed and supported on reinforcing bars or wire mesh (wire mesh) before installation.

Terminal boxes and panels must be installed on the ground and must be waterproof.

Each circuit must be protected by an earth fault protection device operating at 300mA.

Field work is possible for power connection, terminal insulation, and connection between heating cables.

For safety, metal pipes exposed to the public must be protected with a metal barrier or insulating material.

The end of the PTC carbon heating cable must be closed using a terminal key.

After installation is complete, measure the resistance between the buswire and the braid with a 500Vdc insulation resistance tester before pouring concrete.

(Measured value must not be less than 200MΩ)

PTC carbon heating cable must not be disturbed during concrete pouring work.

A flexible conduit must be installed in the section where the PTC carbon heating cable exits from the road to a panel or terminal box.

Only one heating cable must be inserted in the conduit.

In order to cure the concrete, the heating cable must not be powered on for at least 7 days after the concrete is installed.

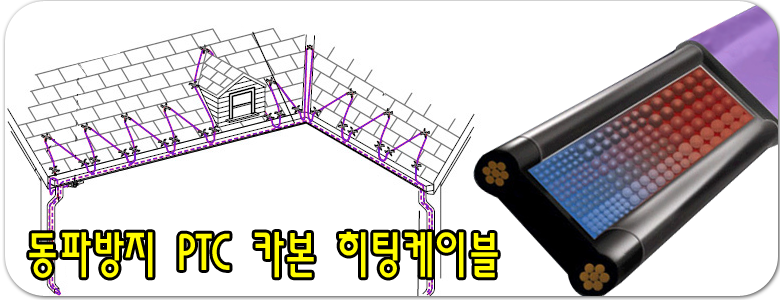

Roof/ditch deicing system

1. Definition of roof & gutter deicing system

A system that consists of self-regulating PTC carbon heating cables and accessories to maintain smooth water flow in the eaves, gutters, and gutters of roofs that are easily clogged by ice or snow

2. Composition and Features

- PTC carbon heating cable has two nickel-plated 16AWG copper wires wrapped in polymer PTC material, and the output changes in response to external temperature.

- Even if overlapped, it does not overheat and is cut to the desired length on site.

- The outer sheath of PTC carbon heating cable accessories must meet NEMA 4X requirements.

* NEMA 4X: It is an enclosure grade that is manufactured for indoor/outdoor use, and is a protective robe that protects from hazards that may occur when an operator approaches a hazardous area. Protection against dust and moisture penetration (rain, sleet, snow, splashing, etc.) corrosion should be provided.

- The system must be installed using the accessories supplied by our company, including the attachment clip for attaching the heating cable to the roof surface and gutter.

- Even if overlapped, it does not overheat and is cut to the desired length on site.

- The outer sheath of PTC carbon heating cable accessories must meet NEMA 4X requirements.

* NEMA 4X: It is an enclosure grade that is manufactured for indoor/outdoor use, and is a protective robe that protects from hazards that may occur when an operator approaches a hazardous area. Protection against dust and moisture penetration (rain, sleet, snow, splashing, etc.) corrosion should be provided.

- The system must be installed using the accessories supplied by our company, including the attachment clip for attaching the heating cable to the roof surface and gutter.

3. Performance

1) Power consumption

-According to IEEE515:2004, it should have output of 55W/m in 0℃ snow or ice and 40W/m in 10℃ atmosphere.

2) Mechanical strength

- The outer jacket must be made of abrasion-resistant fluoropolymer.

- According to IEEE515:2004, there should be no cracks in the jacket even after a minimum 13.5J impact at an installation temperature of -20℃.

- According to IEEE515:2004, there should be no cracking of the jacket or deterioration of insulation properties even at a load of 1500N at room temperature.

3) UV safety

- Cables and accessories must not crack or deteriorate even when exposed to sunlight for a long time.

4) Waterproof

- According to IEEE515:2004, cables and accessories must not deteriorate insulation performance even after being submerged in water for more than 14 days.

-According to IEEE515:2004, it should have output of 55W/m in 0℃ snow or ice and 40W/m in 10℃ atmosphere.

2) Mechanical strength

- The outer jacket must be made of abrasion-resistant fluoropolymer.

- According to IEEE515:2004, there should be no cracks in the jacket even after a minimum 13.5J impact at an installation temperature of -20℃.

- According to IEEE515:2004, there should be no cracking of the jacket or deterioration of insulation properties even at a load of 1500N at room temperature.

3) UV safety

- Cables and accessories must not crack or deteriorate even when exposed to sunlight for a long time.

4) Waterproof

- According to IEEE515:2004, cables and accessories must not deteriorate insulation performance even after being submerged in water for more than 14 days.

4. Control

1) Automatic Snow Controller

- The system operates by automatically detecting snow and ice using the Snow/Ice Dual Sensor and Snow Detector supplied by us.

- Control by installing one or more additional sensors in the drain

2) Control using Thermostat & Manual Switch

- It detects the ambient temperature and controls it with a thermostat or manual switch.

- The system operates by automatically detecting snow and ice using the Snow/Ice Dual Sensor and Snow Detector supplied by us.

- Control by installing one or more additional sensors in the drain

2) Control using Thermostat & Manual Switch

- It detects the ambient temperature and controls it with a thermostat or manual switch.

5. Construction

- After hanging down in the drip tray and in a loop or a straight line in the gutter, hold the gutter to the hanging support and attach it using a loop clip.