We have created a awesome theme

Far far away,behind the word mountains, far from the countries

PTC film heating

Item discription

P.T.C란 Positive Temperature Coefficient

일정온도에 도달하면 전기소모량은 줄면서

발열량은 똑같이 내는 것이 특징입니다

일정온도에 도달하면 전기소모량은 줄면서

발열량은 똑같이 내는 것이 특징입니다

에너지 절약성

PTC의자기제어 기능으로 일반필름

난방대비 25% 에너지절약 합니다

난방대비 25% 에너지절약 합니다

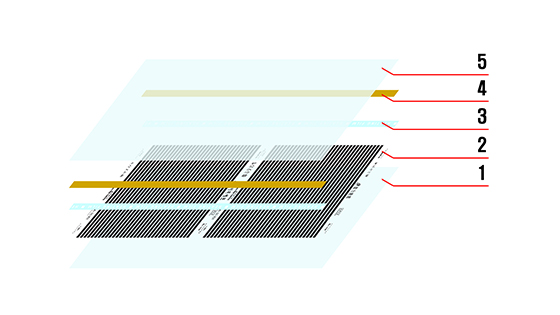

1 - PET film

2 - Carbon

3 - Silver Busbar

4 - Copper foil busbar

5 - Laminex Film

Features

What is PTC (Positive Temperature Coefficient )

It means a device with a constant characteristic temperature coefficient. Below the critical temperature (Tc), the resistance is low and the electric flow is good, so it has the effect of increasing the initial amount of heat,

The effect that the electrical resistance increases in proportion to the temperature from the critical temperature to the melting point (Tm) is called the PTC effect,

According to the PTC effect, the insulation effect is obtained according to the remarkably increased resistance value at the melting point temperature, so useful effects such as prevention of overheating and reduction of power consumption can be realized.

The effect that the electrical resistance increases in proportion to the temperature from the critical temperature to the melting point (Tm) is called the PTC effect,

According to the PTC effect, the insulation effect is obtained according to the remarkably increased resistance value at the melting point temperature, so useful effects such as prevention of overheating and reduction of power consumption can be realized.

In the P.T.C Heating Film, the particles of the heater themselves act as a temperature sensor and the temperature rises.

Controls power consumption and prevents overheating by detecting only the current and controlling the amount of heat

It is possible to realize a heating system that is more economical and safer than any other underfloor heating

P.T.C Heating Film adjusts the resistance of the film itself without a temperature controller when the temperature of the film heater changes. This is a smart heating film that automatically controls power consumption.

P.T.C Heating Film adjusts the resistance of the film itself without a temperature controller when the temperature of the film heater changes. This is a smart heating film that automatically controls power consumption.

* General AC 220V power consumption is used

(After 1 minute)

About 1 minute after power is supplied to the PTC heating film, the surface temperature has already reached 25℃ (Fig. ①)

According to the electrical resistance-temperature graph on the left, the power consumption is 220~240Watt/m2, which is almost the same level as the existing heating film.

According to the electrical resistance-temperature graph on the left, the power consumption is 220~240Watt/m2, which is almost the same level as the existing heating film.

(after 5 minutes)

When the film continues to heat up and reaches 40-45℃ suitable for heating, it will burn at 160-180Watts per square meter

The power consumption is reduced, and when the floor is installed, the time for the surface temperature of the PTC heating film to reach 40~45 ℃ (Fig. ②) is

It takes about 5 minutes (about 2 minutes in the case of a long board). Therefore, after about 5 minutes, it has already been reduced by 26% compared to the conventional heating film

It maintains 40~45℃ with only 160~180watt /㎡ of power.

The power consumption is reduced, and when the floor is installed, the time for the surface temperature of the PTC heating film to reach 40~45 ℃ (Fig. ②) is

It takes about 5 minutes (about 2 minutes in the case of a long board). Therefore, after about 5 minutes, it has already been reduced by 26% compared to the conventional heating film

It maintains 40~45℃ with only 160~180watt /㎡ of power.

(Continuous Heating)

When the temperature of the floor surface reaches 40 ℃ due to continuous heating, the surface of the floor in contact with the PTC heating film

The lower surface reaches 55℃ or higher and reaches ③ in the left graph to maintain heating at 150Watt/㎡

About 35% less than the existing heating film.

The lower surface reaches 55℃ or higher and reaches ③ in the left graph to maintain heating at 150Watt/㎡

About 35% less than the existing heating film.

Energy comparison table

| Classification | Classification | Oil/Gas boiler | Electric stone panel | Far infrared film heating |

|---|---|---|---|---|

| Construction method | How to install | Wet construction possible | Dry construction possible | Dry construction possible |

| Boiler room | Separate boiler room required | None | None | |

| Heating pipe | exposed | None | None | |

| Construction period | Takes 4-5 days | Take 1-2 days | Takes 1 day | |

| Heating method | Fuel used | fossil fuel | Electricity | Electricity |

| Heating method | conduction, convection | Evangelism | Copy string | |

| Far infrared generation | None | None | 90% or more | |

| Noise and combustion dust | occurred | None | None | |

| Electromagnetic wave generation | None | High | Has harmless level to human body | |

| Repair method | Freeze | Freeze occurs | No freezing | No freezing |

| Remodeling | Main repair (concrete dismantling required) | Easy | Easy | |

| Previous installation | Boiler equipment is possible, piping is not allowed | Easy | Easy | |

| Disadvantages | Oil fuel cost | Cannot be used when disconnected | Separate installation of water heater |